The Ultimate Guide to Short Drama: Captivating Stories in Minutes

In today’s fast-paced digital world, short dramas have emerged as a powerful storytelling medium. These bite-sized narratives deliver emotional depth and engaging plots in just a few minutes, making them perfect for modern viewers.

What Makes Short Drama So Engaging?

Short dramas excel at capturing attention quickly. Through concise scripts, strong character development, and impactful visuals, they create immersive experiences that resonate deeply with audiences.

Popular Short Drama Formats

From romance and suspense to comedy and inspiration, short dramas span various genres. Platforms like social media and streaming services have made it easier than ever to produce and share these compelling stories.

Benefits of Watching Short Dramas

Short dramas offer quick entertainment without long time commitments. They’re ideal for breaks, commutes, or whenever you need a brief escape. Their shareable nature also helps them go viral, reaching global audiences.

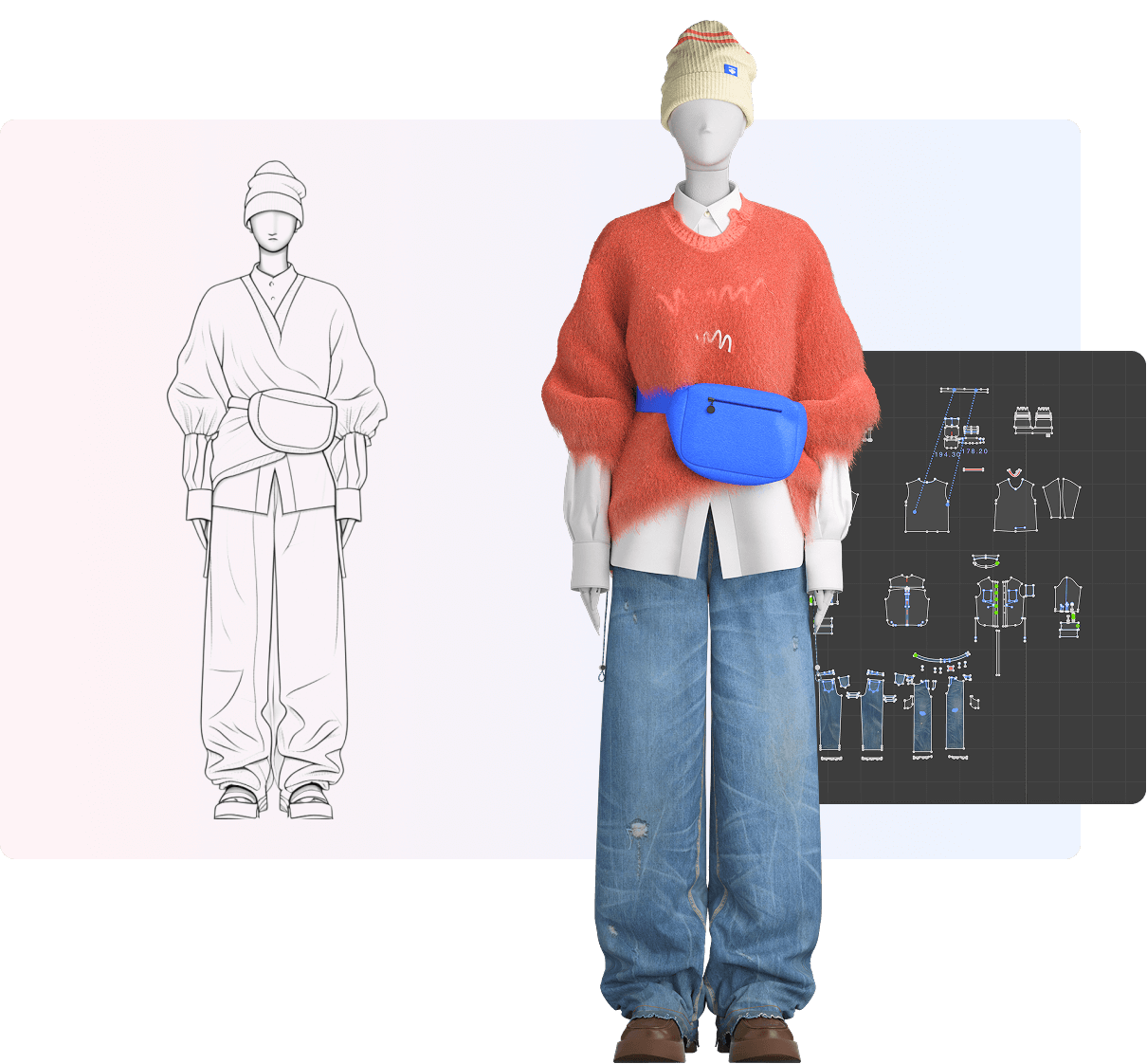

How to Create Your Own Short Drama

Starting is simple: brainstorm a concept, write a tight script, gather a small crew, and focus on high-quality production. Many creators use smartphones and basic editing tools to bring their ideas to life.

FAQs About Short Drama

What defines a short drama?

A short drama is a brief narrative video, typically under 10 minutes, designed to convey a complete story with emotional impact.

Where can I watch short dramas?

You can find them on platforms like YouTube, TikTok, and dedicated apps. For an excellent example, check out this Short Drama.

Can short dramas be profitable?

Yes, through ads, sponsorships, and platform monetization, creators can earn revenue while building a loyal audience.

Ready to Dive Into Short Drama?

Explore the exciting world of short dramas today! Whether you’re a viewer or a creator, there’s never been a better time to engage with this dynamic format. Start watching or creating your own now—your next favorite story is just minutes away.